Extend the Life of Your Fleet

Haulage and bus companies can maximise the lifespan of their fleets, improve the productivity of their workshops, reduce downtime and even identify potential breakdowns before they occur through oil analysis.

The purpose of engine oil is to lubricate, clean and cool the engine and its components. If it is in any way contaminated, problems can occur, including engine failure.

Whether they carry passengers or goods, for hard-working vehicles it is wise to incorporate regular oil analysis into a programme of planned vehicle maintenance as this can reveal useful diagnostic information.

What does this process achieve?

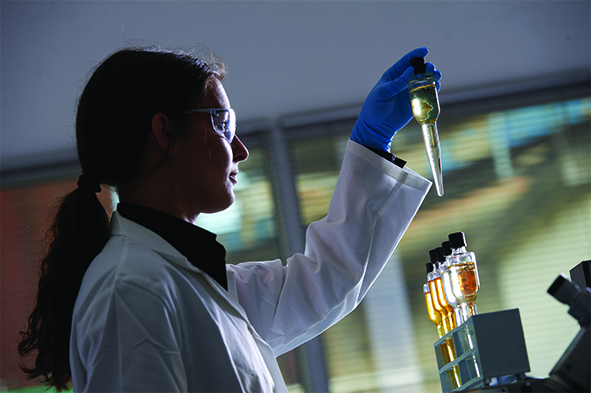

Oil analysis typically consists of taking a representative sample, like a blood test, to be analysed in a laboratory, with the results then enabling the fleet manager to take any appropriate action needed.

The oil samples seek to identify several different contaminants that can cause increased wear on vehicle components.

Contaminants such as dirt and dust may be abrasive but can get inside engine components. If ignored, abrasives in the lubricant will impact the reliability and lifespan of the vehicle.

Although dust and dirt are the most prevalent, another contaminant is water, which can get into the system through cracked seals. If water is present, it reduces the effectiveness of the lubricant, leading to greater wear.

Just as dust and water can get into the system, so too can coolant. If this happens, it can damage the vehicle’s bearings, pistons and other engine components.

Oil analysis can also establish if there is any fuel in the lubricant. Oil that is diluted with fuel can lead to the viscosity being too low to withstand heavy loads and speeds, resulting in friction between metal surfaces and wear on the components.

Our professional oil analysis service

TotalEnergies ANAC (Analysis Compared) oil analysis service utilises expert diagnostic and preventative information to help identify and prevent engine health issues before they become serious problems.

With over 4,000,000 diagnoses since its introduction and over 470,000 mechanical units monitored just by analysing a simple oil sample, Total can examine engine reliability, therefore identifying potential problems across mechanical parts, including engines, transmissions, hydraulics and coolants.

With a suite of fluid analyses specially adapted for fleet maintenance and performance maximisation, the service combines calculated wear limits for components, including engine oil, gearbox oil, axle oil, hydraulic oil, synthetic oil and cooling fluid analysis. It can predict the likelihood of wear and part failures, such as head gasket and air filters, and can diagnose underlying issues – ineffective water pumps, for example – thanks to an unrivalled database of over four million records.

ANAC allows fleet managers to look at the wear coefficient for engines, to optimise oil change frequencies, plan preventative maintenance, and take the hassle out of planning servicing dates across large fleets.

The accurate planning of maintenance schedules, oil change times and pre-warning of mechanical issues combine to improve the reliability and performance of fleets, in turn increasing their lifespan.

Keeping buses and HGVs operational is vital to fleet operators and oil analysis can play a critical role in understanding engine health, as well as saving fleet managers time and money in repairs, replacements and lost revenue.

ANAC oil analysis – key benefits

- Reduce operating costs

- Anticipate and plan maintenance operations

- Increase equipment lifespan

- Improve equipment reliability and performance

- Optimise oil change frequency