Choosing the Right Coolant for Your Bus or Coach

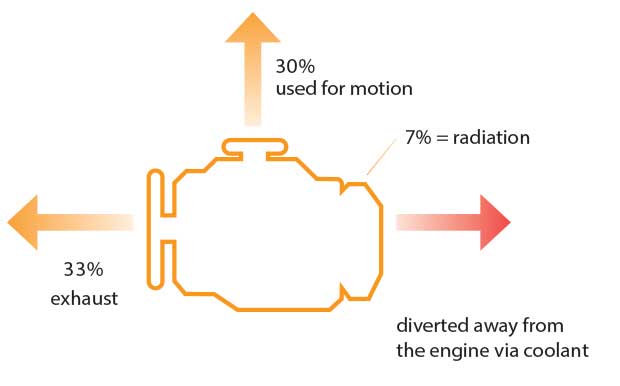

Coolant for buses has become more and more important over the last few years as the engines being manufactured for them have become more and more complicated. These new bus engines are running hotter than before which causes more pressure on their cooling systems. Coolants for bus cooling systems help the engine run better by carrying the excess heat prevented in the bus engine away from the block, preventing the engine from overheating and breaking down. A bus engine requires approx. 30% of the energy produced by the engine to run and move the bus. The other 70% of this energy converts into heat which can damage the engine if not removed, some of this heat escapes through the exhaust system, thus leaving a requirement for a cooling system to remove the remaining unwanted heat.

From bus to bus the cooling systems are different and have different requirements from the coolant added to them, meaning there is a requirement for different types of coolant for different buses. If the coolant within the buses cooling system breaks down this can cause a leak into the engine which can damage the bus engine or the system may stop working meaning the engine may overheat and can also be damaged this way. Therefore understanding the different types of coolant of buses and how to choose the right one is very important.

Types of Coolant for Buses

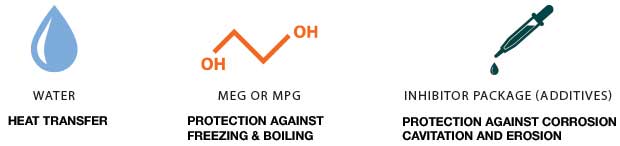

A bus coolant is made up from 3 components; MEG/MPG, An Inhibitor Package & Water.

- Water is used in coolants as it is the best heat transfer fluid and is inexpensive, however, the water in today’s coolants is demineralized water so as to reduce any impact that minerals in ordinary water could cause to the cooling system.

- MEG or MPG are added to bus coolant depending on the operating climates of the engines. These are the base fluids to the coolant and the type used is influenced by a number of factors including risk of corrosion, toxicity, freezing point etc. In a climate like ours the coolants required need to be able to resist freezing during the winter whilst also resist boiling or vaporising in the hot summer weather. The type of MEG or MPG also depends on the type of inhibitor package added to the coolant.

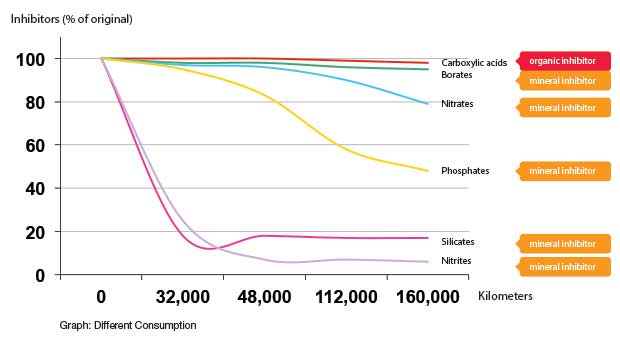

- Inhibitor Packages are added to coolants depending on the type of coolant been manufactured and are added to counteract the risk of corrosion by the water to the cooling system parts. This small component of coolant for buses has the biggest effect as coolants with different packages cannot be mixed and it is these packages that meet the requirements set out by the manufacturers. There are two types of packages being used today; Mineral inhibitor technology (Traditional) and Organic Additive Technology (OAT).

Choosing the Right Coolant for Buses

There are a number of influences that determine the coolant required for a specific bus. These are:

- Exchange Heat Efficiency

- Protection required against corrosion & cavitation

- Meeting the manufacturer’s requirement specifications for the particular engine.

- Boiling Point

- Freezing Point

Another influence that a lot of people follow is the colour of the coolant however this is an incorrect way of choosing a coolant as the colour is just the dye added and has no impact on the performance or specifications of the coolant and manufacturers may use different colours for different types of coolants which could lead you to choose the wrong coolant if you choose it by colour.

To help you choose the right coolant for your bus you can use the Which Oil? Oil finder app as this also gives you the type of coolant that your bus requires as well as the oils. You can also talk to Finol Oils Ltd in Dublin to discuss the full range of Total Coolant for buses available.