Traditional antifreeze and coolants were mainly blue or green no matter what specific brand you chose. Antifreeze was mixed 50/50 with water and then poured into the radiator. As the engine operated, the antifreeze completed its primary function of carrying heat to the radiator, averting freezing and defending against corrosion within the cooling system. You then changed the antifreeze at the recommended service period.

Today, antifreeze technology is available in a wide array of ranges and colours causing confusion as to what antifreeze is best. Rather than colour, we should be looking at how it is produced. Manufacturers make coolant with ethylene glycol, a compound produced from ethylene (ethylene oxide) or with the compound propylene glycol.

How antifreeze and coolants have evolved

Inorganic Acid Technology (IAT) is the chemical foundation for the original green or blue antifreeze. IAT contains either ethylene glycol or propylene glycol and is mainly built up with silicate or phosphate additives to increase its compatibility with metal cooling system components. The generally recommended replacement interval is every year.

WHAT DO IAT AND OAT MEAN?

As we have seen, Inorganic acid technology (IAT) is the chemical composition for the traditional green, yellow or blue antifreeze.

Organic acid technology (OAT) on the other hand is a Long Life Coolant usually made of ethylene glycol and is commonly used in Europe. It also has a vastly superior recommended replacement is 5 years or 240,000km

Hybrid Organic Acid Technology (HOAT) is a combination of IAT and OAT with nitrites and actually existed prior to the development of OAT technology. The generally recommended replacement interval is 3 years or 240,000km.

WHY ARE THERE SO MANY VARIANTS?

As the need for antifreeze and coolants grew, manufacturers became increasingly aware of the different needs for each region. This meant that different compounds and formulas were needed to suit specific regions. European countries had extremely hard water. As antifreeze and water are a 50/50 mix, water quality drastically impacts the overall mix, water quality drastically impacts the overall mix. European manufacturers then began to move away from phosphate-based technology because of the tendency to form scale. On the other side of the world, Japanese manufacturers began to move away from silicates, due to issues with silicate gel drop out.

As well as being better corrosion inhibitors for the global market, other issues sped up formula change. Toxicity is behind the use of propylene glycol rather than ethylene glycol, while the promise of longer lasting engine protection and less maintenance spur development of the newest formulations.

WILL ANTIFREEZE DEGRADE OVER TIME?

In short, yes engine antifreeze will break down, (producing acidic decomposition products. Antifreeze buffering agents counteract this acidity. Since antifreeze will leak over time, most systems are refilled or added to, extending its life depending on what antifreeze you use.

CAN YOU MIX ANTIFREEZE?

It is best to use the same type of coolant originally used in your vehicle, or the vehicle manufacturer’s recommendations. According to experts within the industry, if you don’t know what coolant is in the vehicle and you add another brand, nothing bad will occur. But if the mixture of the technologies is close to 50%, the effectiveness of each coolant’s inhibitor package is affected. In general, if mixing coolants, the recommended coolant change period will fall to that of the shorter life coolant.

management is essential

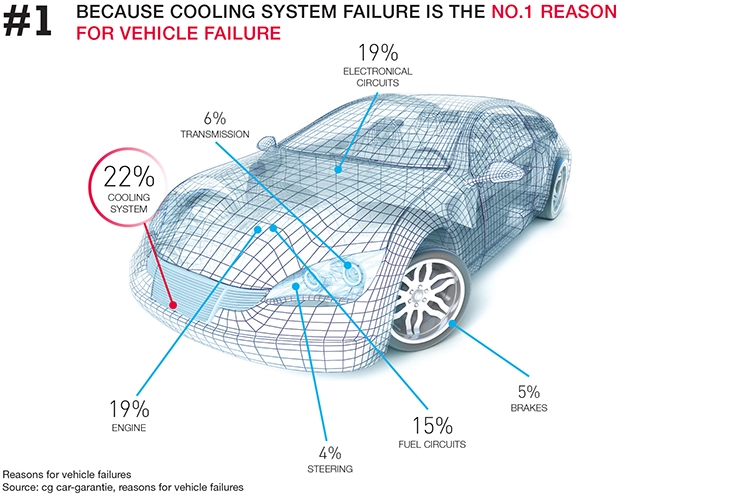

As you have seen with anything automotive, correct maintenance is essential to longevity. Just as important as the type of antifreeze you use is the ability to maintain the cooling system properly. In fact, cooling system failure is the number 1 reason for vehicle failure. To maintain the system, you must preserve freeze point protection and proper coolant level. Coolants work best at the ideal freeze point mixture, which usually means a 50/50 antifreeze-to-water mixture. Also maintaining proper freeze point protection ensures corrosion inhibitors exist at recommended levels.

Vehicle manufacturers create cooling systems to operate with the optimum level of antifreeze. A system that is continuously low on coolant creates an extremely corrosive environment due to the aggressive nature of the glycol/water mix. To check your coolant system capacity, you will find the details in your vehicle’s manual.

DISTILLED WATER IS BEST

In many countries, including Ireland, tap water contains minerals such as magnesium and calcium. These minerals can form deposits in a cooling system, especially on the engine’s hottest parts. The water you use to mix the antifreeze is critical. All pre-mixed coolants are produced with distilled water. Use distilled water, not tap or filtered water, when you refill any cooling system.

continuous engine protection

The proper coolant level is still extremely important after turning off the engine. As the coolant stops flowing and the engine temperature increases dramatically, areas of residual boiling can send large shockwaves through the engine causing havoc on components, especially those made of aluminium.

Why Choose Finol coolants

Designed around OAT inhibitors, Finol Coolants & Antifreeze provide a solution for issues that arise from the complexity and technological advances within modern vehicles. Low additive depletion rate guarantees longer coolant operational life and complete coolant system protection under all conditions. This longer life allows for extended drain intervals with reduced maintenance downtime, less coolant replacement costs in the long run and less possibility of harming the environment.

Browse our full range of Antifreeze & Coolants where you will easily find a product that suits your lubrication needs. If you need to speak to an expert or have any queries, you can speak to one of our highly experienced area sales managers here or can contact the office at 01-4555484